Rotating Machinery Diagnostics and Vibration Analysis

Factory acceptance testing of large, industrial rotating machines often requires complete and accurate documentation of vibration characteristics including measurements for shaft and housing vibration analysis.

Large Industrial Rotating Machinery Diagnostics

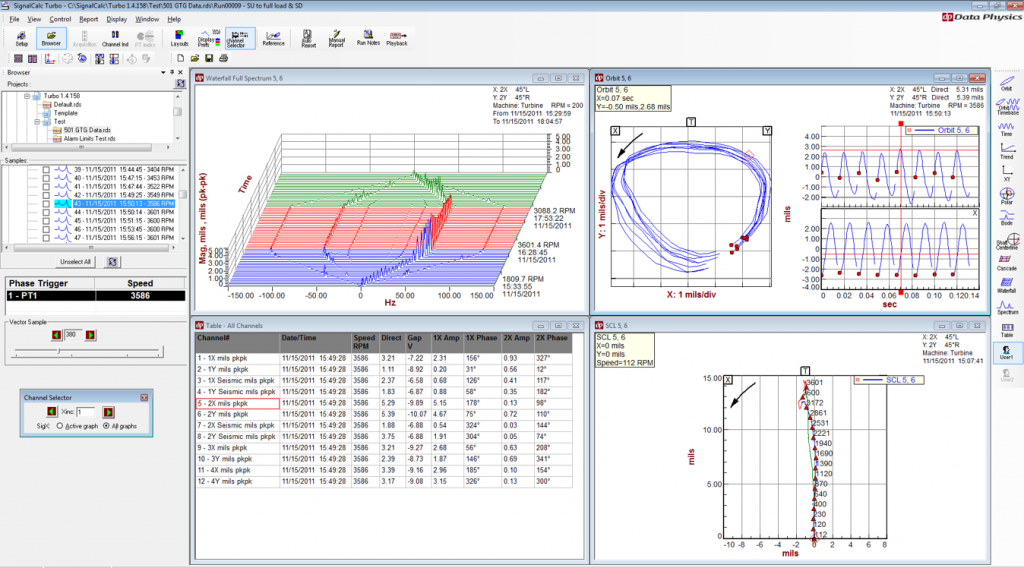

SignalCalc Turbo analyzer provides graphical measurement tools for analyzing fluid-film bearing machines. With a pair of proximity probes mounted on the shaft, a variety of diagnostic signals can be displayed to properly assess rotating machinery health.

Orbit Plots

Unfiltered or filtered 2D orbit plots

Orbit Timebase

Filtered or unfiltered time domain displays

Trend Plots

RPM, Amplitude, Phase, and more vs. Time

Polar Plots and Shaft Centerlines

Shaft Centerline, or filtered Polar Plots

Bode Plots

Filtered and unfiltered Bode plot

Waterfall / Cascade Plots

RPM based waterfall displays

Table Values

Filtered amplitude/phase vs time

Machinery Structural Analysis

Rotating machinery dynamics are best understood when structural and rotary dynamics are considered. With RPM measurements available throughout all structural analysis applications, SignalCalc 900 offers a robust solution to analyzing complex rotating machines and their supporting structures.

RPM Measurement

Measure RPM accurately with the high speed tachometer hardware

RPM Triggering

Trigger measurements based on RPM or RPM increments to collect steady state or ramp-up/ramp-down data

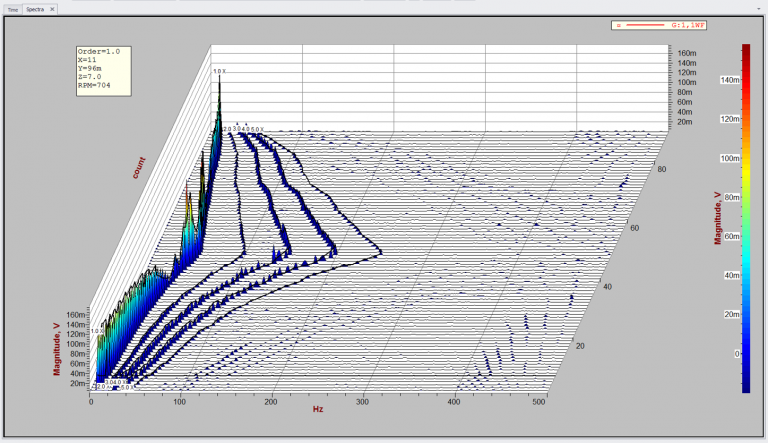

RPM based 3D plots

Visualize structural resonances and their excitation caused by rotating machines on 3D Waterfall or other plots

Engine Order Analysis

Automotive test engineers use order tracking methods to evaluate both rotating components and vehicle drivelines. Order tracking easily separates forced vibrations caused by the revving engine from the structural response of resonances.

Order Normalization

Specify RPM range of interest, the max order, and the desired delta order and the system automatically selects the propper measurement parameters.

3D Plot Visualization

Choose from waterfalls, color mesh, color cascade, campbell plots, spectrograms, and more.

Simultaneous FFT Measurements

Simultaneously run FFT measurements (multi-measurement) to take FFT based and RPM based measurements simultaneously – no need for post processing