Satellite Qualification Testing

Mitigating Risk During Satellite Qualification

Structural testing of a precision engineered satellite can be nerve racking. When selecting a vibration test system to test a valuable test article, risk mitigation is critical. Data Physics has been involved in testing some of the most valuable satellites ever put on a shaker – and developed the 900 Series controller from the ground up with advanced safety features to ensure testing success.

We get it – the shaker system isn’t the focus of your test. The shaker system needs to protect the test article from overtest or transients at all costs.

Data Physics has designed a system which protects your test article at all costs – with all components of the vibration test system working together to prevent unexpected vibrations

A Complete Satellite Qualification Safety System

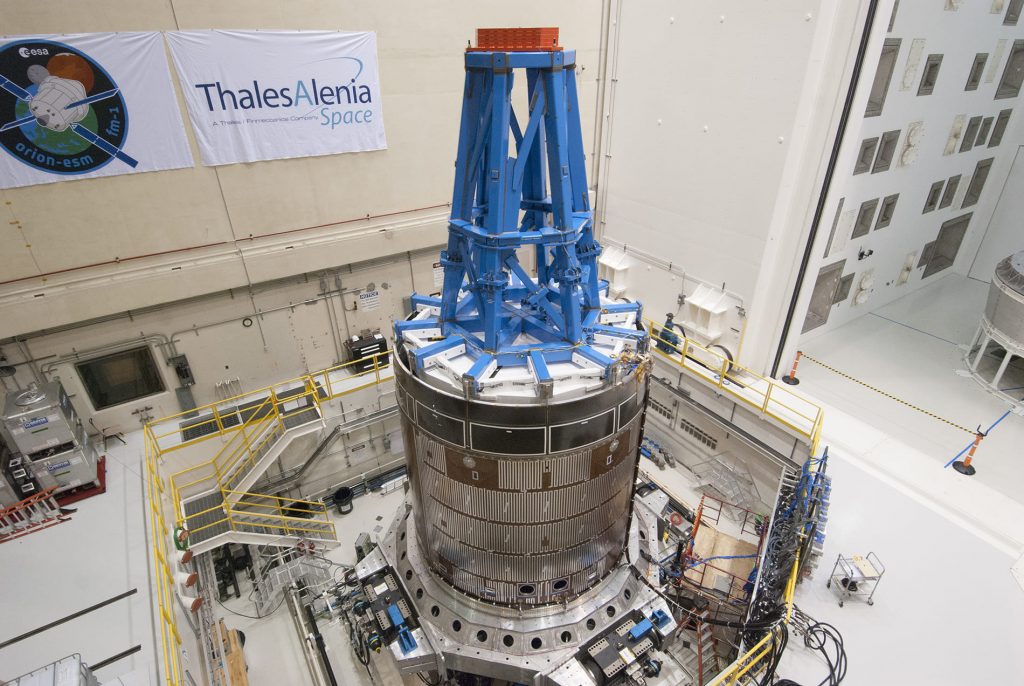

Data Physics and NVT Group partner company Team Corporation have engineered a test safety system capable of protecting valuable test articles from unexpected events – even a complete loss of 480 V power.

The safety system includes modifications to all subsystems involved in the test – the shaker, amplifiers, hydraulic guidance, and vibration controller. In the case of any subsystem failure, the controller ramps down the test before any transients can be imparted to the test article.

Such a test system was used to test the James Webb Space Telescope at NASA Goddard in 2017.

Vibration Control for Satellite Qualification

The 900 Series controller was designed with safety in mind. It uses a decentralized design is intrinsically safe from unexpected computer failures during a test.

The 900 Series has the ability to compute math channels for summed moments/forces, displacements, and more (gap-free). Math channels can be used as a part of the notching or control algorithms.

The 900 Series platform has unique features which eliminate the need for post processing data, eliminating the need for post processing and streamlining the tedious task of identifying issues with the vibration test.

Analysis System for Satellite Qualification

Monitor hundreds or thousands of measurement channels in during a shaker vibration test – with special features customized for satellite test monitoring.

Such features include the ability to define tolerance profiles for individual channels, monitor for transients, and to signal the controller to ramp down the test if any anomalies are detected.

Timing is critical – and SignalCalc 900 is optimized to quickly direct the controller to shut down when any irregularities are detected.

Guided Head Expanders

Overturning moments must be contained when exciting a large test article. Shaker armatures are not designed to handle large overturning moments, and external guidance bearings are often required to ensure overturning moments don’t damage the test system; and ultimately the device under test.

Data Physics and NVT Group partner company Team Corporation specializes in custom guidance bearings to constrain overturning moments that are generated during a vibration test.