Last Updated on March 21, 2024 by dpnew

The Data Physics 900 Series vibration controller: Uniquely designed to mitigate risks during testing.

The primary objective of satellite vibration testing in the laboratory environment is to validate survivability of flight hardware during launch. But structural vibration testing of a precision-engineered satellite also introduces risk of failure modes that could damage flight hardware during testing.

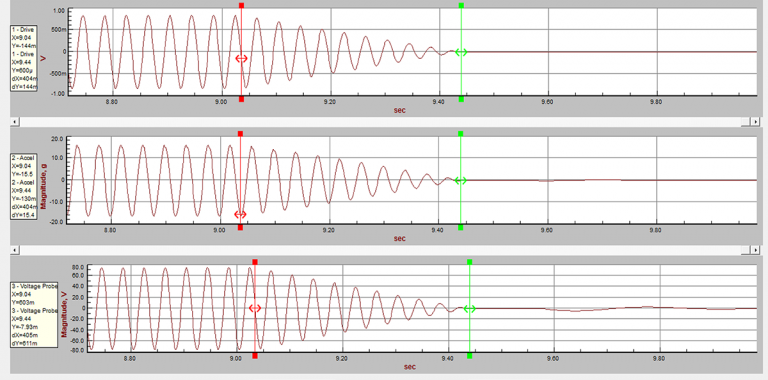

To mitigate these risks, Data Physics developed the 900 Series Vibration Controller with advanced, built-in safety features that protect valuable test articles from potentially damaging transients given an abort, by insuring safe ramp down of the shaker system.

When integrated with Data Physics’ Soft Shutdown amplifiers and shakers, the controller can even safely ramp down a shaker system given a complete loss of 480 V facility power.

The James Webb Space Telescope was successfully tested with vibration systems specially designed by Data Physics and Team Corporation that incorporated advanced safety features.

To learn more about the proven safety features of the 900 Series Vibration Controller, download our info sheet: