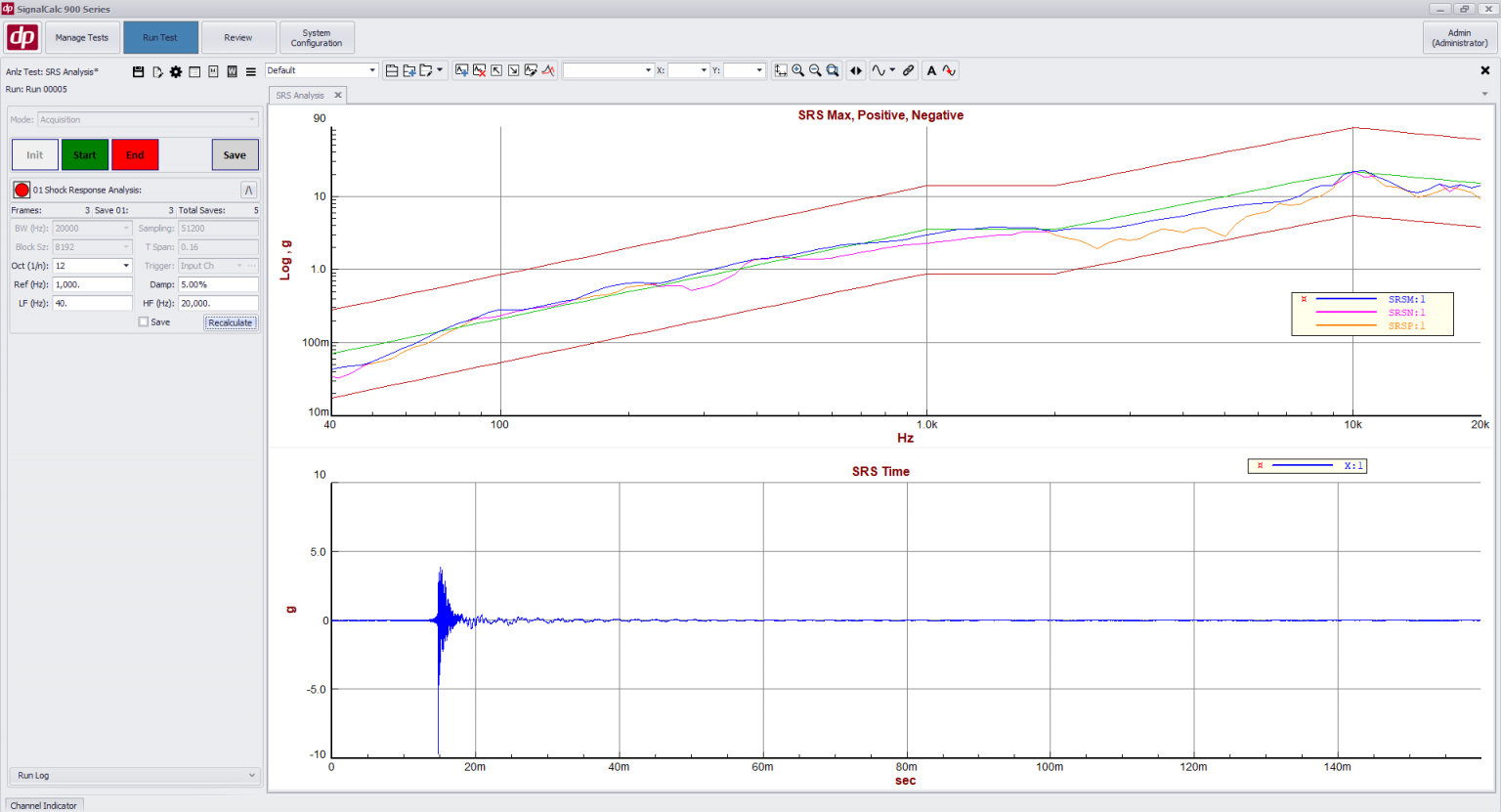

shock response spectrum analysis

Analyze the Damage Potential of Shock Events Quickly and in Realtime

The SRS Analysis module quickly captures triggered vibration events, displays its SRS, and allows the live recomputation of the SRS in realtime with different measurement parameter – streamliming the process of Shock Response Analysis.

Triggered SRS Measurements

Trigger acquisition based on sensors

Trigger the measurement based on the level and slope of the input channel

Tolerance Bands

Enter Tolerance bands for pass/fail error checking

Pass/Fail Criterion

Enter Tolerance bands for pass/fail error checking

Live Manipulation of Analysis Parameters

SRS type, octave spacing and critical damping percentage can be modified to recompute the SRS during the measurement

Integration/Differentiation of Captured Signals

Display data in acceleration, velocity and displacement

Sample Rates up to 200 kHz

Accurate measurement of high frequency shock events

Advanced Analysis Capabilities

Recording and Playback Analysis

Record shock data and individually trigger and analyze individual shock events within the recording

Simultaneous Multi Measurement

Combine SRS analysis with other measurement types like FFTs to streamline data acquisition and analysis