High Intensity Acoustic Noise Generation

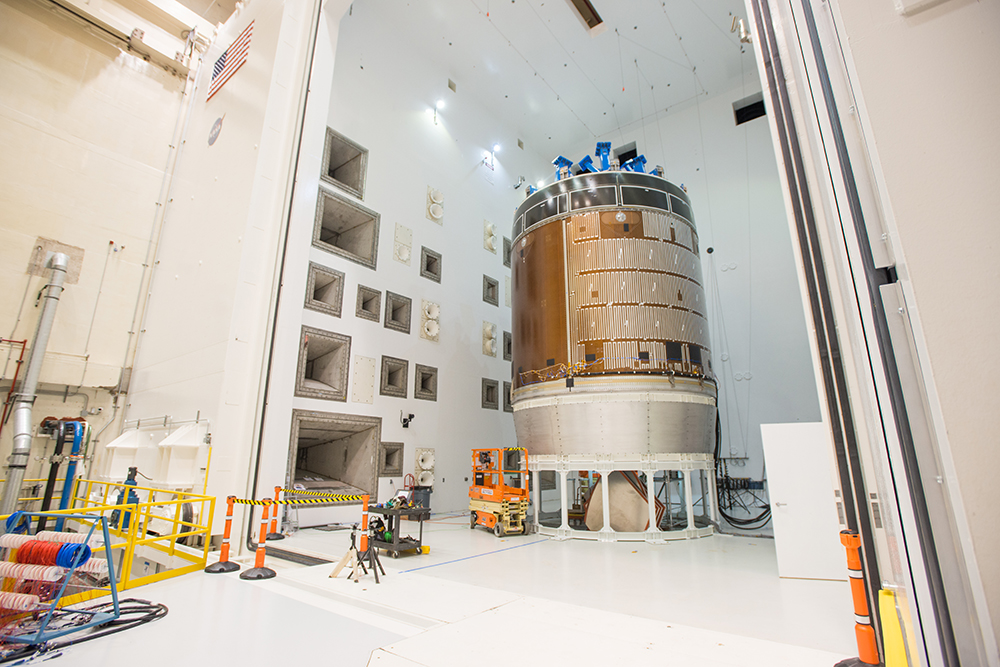

Acoustic Testing is Essential to Ensure a Satellite can Withstand the Intense Acoustic Energy Emitted During Launch

High intensity acoustic tests are critical to ensure a satellite can withstand its launch environment. There are various accepted methods to test put a satellite through such a test which include Reverberant Acoustic Testing, Progressive Wave Tube Testing, or Direct Field Acoustic Testing.

Acoustic Noise Generators and Controllers for Reverberant Acoustic Test Facilities (RATF) and Progressive Wave Tubes (PWT)

Blasting a satellite with a shaped noise profile begins with noise generators. Data Physics noise generators offer a complete turnkey system including the acoustic transducer, a 10 KVA amplifier, field power supply, and a cooling unit. They can be used in new installations or to retrofit existing acoustic horns.

The Data Physics APG Acoustic Noise Generators are widely used in PWTs and RATFs alike.

RATFs and PWTs are controlled by the Acoustic Controller using feedback control and microphones.