Rotating Machinery Analysis

Analyze Vibrations Caused by Rotating Machinery by Triggering or Normalizing Data Based on the Rotating Speed of the Machine

RPM Analysis provides measurements synchronized to the speed of a rotating shaft. A high speed tach channel reads the RPM from the tachometer signal, and it can be used to trigger measurements or to pace waterfall displays.

RPM Detection Modes

RPM Sweep

System continuously monitors rpm during a ramp-up or coast down and triggers measurements based on a specified RPM interval

RPM Stepped

When the shaft reaches the specified rpm, system performs an averaged measurement reducing the signal noise

RPM Steady

Measurements are taken when the shaft speed is within a specified rpm band. Useful for monitoring a shaft that is drifting around a specific rpm

RPM Delta

Mode is similar to the RPM Sweep mode but allows for abrupt changes in sweep direction

Auto and Multi Tach Support

System automatically detects rpm information from a single or multiple tachometer channels; pacing and synchronous triggering can be enabled on the same channel or on different tach channels

Data Export

Export to ASCII/CSV, MEscope, UFF, SDF and Matlab

Rotating Machinery Analysis Options

RPM Measurement

FFT-based fixed bandwidth technique ideal for steady state or slow changing rpm measurements

Synchronous Averaging

Process removes the contribution of asynchronous vibration sources from a time or linear spectral average

Automatic Start and Stop Recording Using Events

Event-based start and stop recording ensures that the desired data is captured

Demodulation Measurement

Computes amplitude and phase/frequency domain demodulation by computing the Hilbert transform. Useful when signals of interest are mixed with other signals as modulation of frequency or amplitude

Waterfall Analysis

Waterfall analysis combines rotation speed, amplitude and orders on the same graph, enhancing data clarity; helps differentiate structural resonances from order-related vibration

Order Tracking Measurement

Uses a resampling technique to synchronize the sampling of input signals to the instantaneous angular velocity of the machine, providing revolution histories and order spectra. Ideal for high speed, rapidly accelerating or decelerating measurements

Custom Reports and Data Review/Export

Fully Customizable Plots

Include readouts including test parameters, customer and test article name, operator, test time, etc

Overlay Data

Data from one or more runs/saves can be overlaid in Review Mode within seconds. The overlaid plots can be placed in a report.

Data Export

Data can be exported automatically during or after a test

Create Custom Report Templates in Word

Create a report template in Microsoft Word and have SignalCalc 900 populate the report parameters, plots, and images automatically after each test (DP900-68)

Images and Media

Attach images of the test article or setup and have them printed in the report

Generate Reports Anywhere

Generate Reports on the PC that conducted the test, or on any networked PC

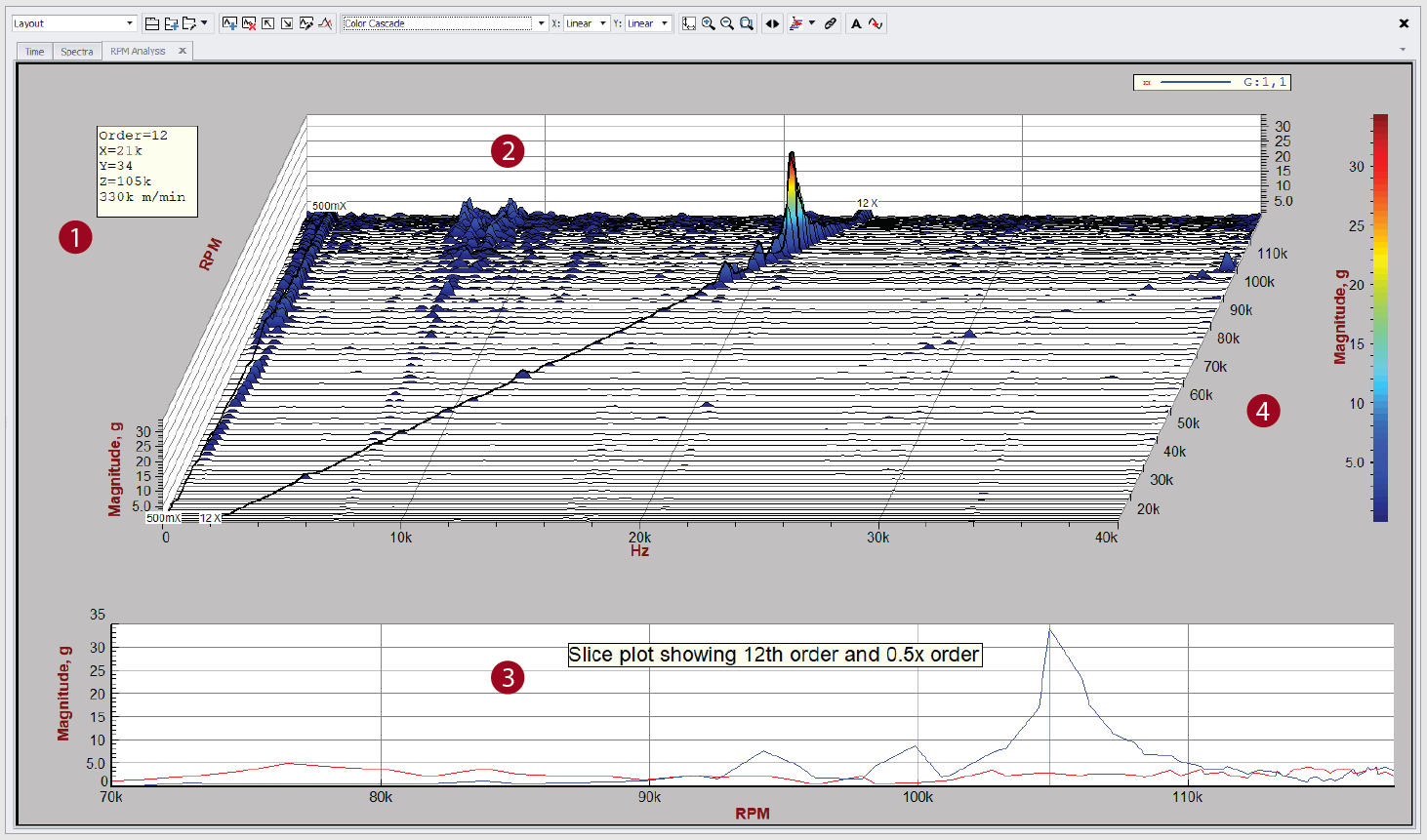

1 Waterfall Compression

Allows data compression along the X-axis and/ or the Z-axis for faster waterfall displays. The choices are All, Every Nth, Max Nth, Min Nth, Average Nth and Auto. Compression applied is displayed in the WF legend.

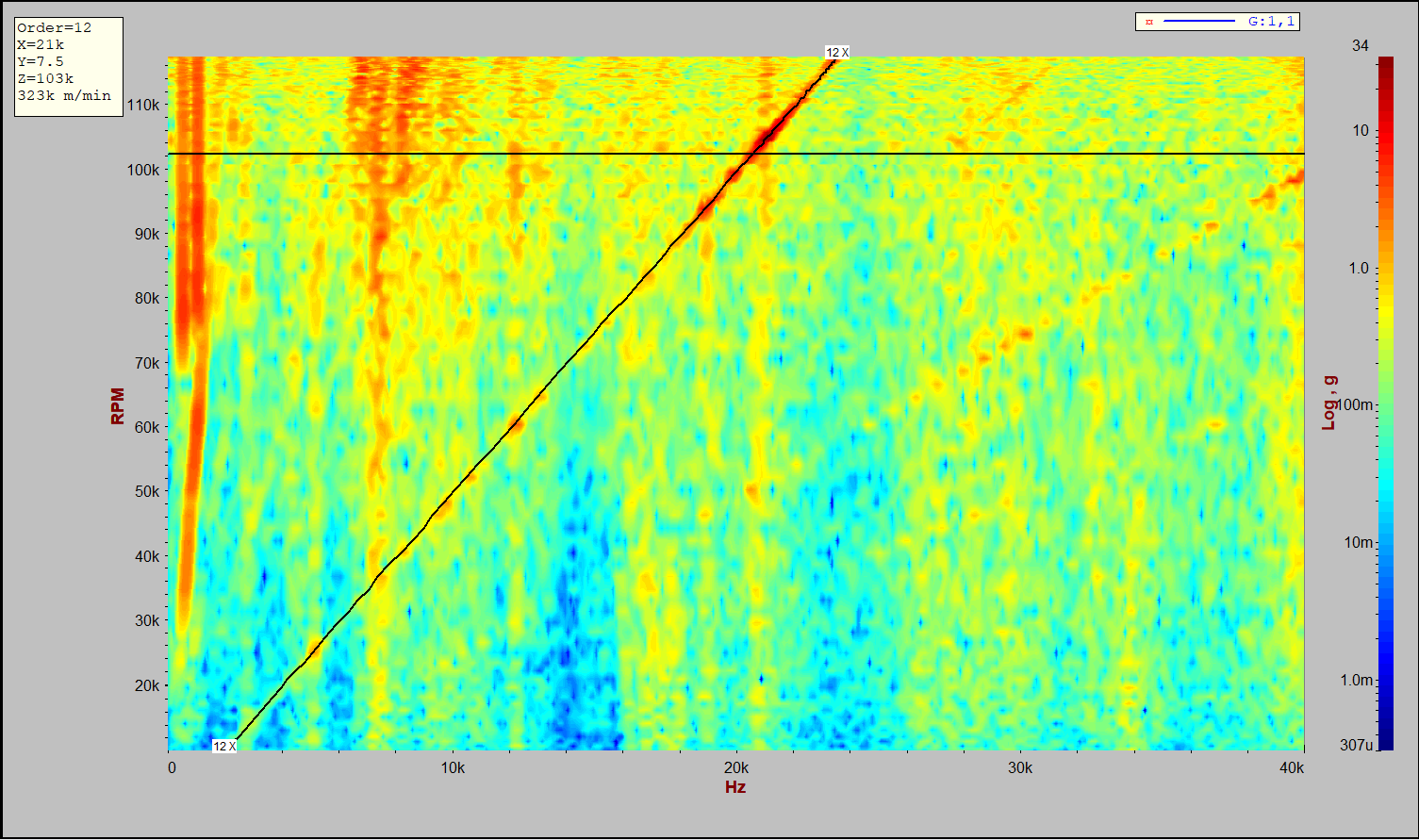

2 Waterfall Formats

Waterfall plots can be displayed in different formats color cascades, surface maps, spectrograms, color mesh or Campbell diagrams.

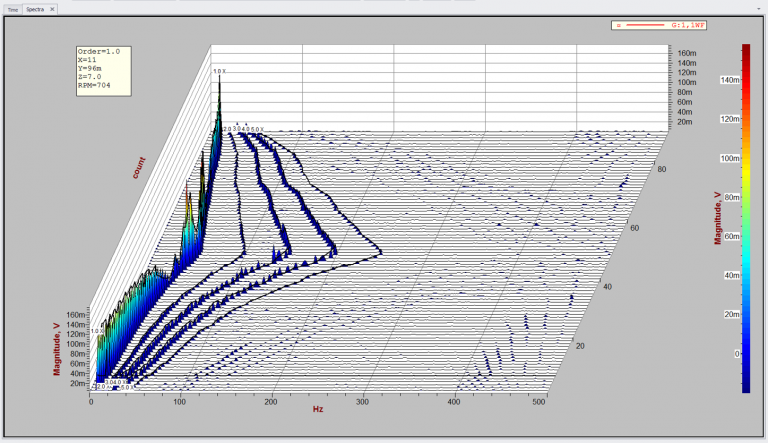

3 Waterfall Child Window

Allows the user to examine each individual

spectrum or order plot in detail, overlay multiple traces and compare them against maximum or RMS amplitude values as a function of shaft rotating speed or order.

4 RPM Axis

Z-axis on the WF graph can be customized to display rpm, count or time.