How an innovative California company’s advanced aerospace components are made better by harnessing the power of the Data Physics 900 Series dynamic signal analyzer.

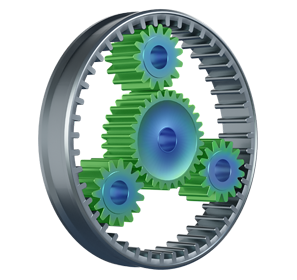

Our customer, Amorphology is the first company to develop the commercialization of bulk metallic glass flexsplines for strain wave gears, planetary gears and other precision gearboxes and precision components with a micron level of precision.

Following a proprietary process, Amorphology manufactures custom unlubricated gearboxes from exotic bulk metallic glasses, or BMGs, for aerospace applications. Without lubricant, Amorphology’s gears last up to 6x-7x times longer than normal stainless steel gears, and they project similar out-performance with lubricant in upcoming studies. They utilize the 900 Series dynamic signal analyzer to evaluate the performance of their materials and improve the lifespan of their products. By using the 900 Series, they have been able to quickly identify the root cause of failures and develop new materials and designs that can withstand the extreme conditions of space.

Now they are bringing that technology back to Earth, for applications where lubrication is not an option.

Using Amorphous Metals, also known as Bulk Metallic Glasses (BMGs), Amorphology casts high-resolution net-shape parts, including gears and gear components. Cast amorphous parts display high hardness and wear resistance, are able to operate in un-lubricated environments, exhibit high surface finishes, and are corrosion-resistant. In particular, the casting of BMGs excels for small parts, including small components, or gears with complex geometries.

During material analysis, Amorphology is able to find areas of unwanted resonance and mitigate these through multiple product iterations to significantly improve the lifespan of their products. The importance of lifespan cannot be underestimated in space applications due to the lack of replacement parts and installation in space applications.

With its advanced analysis capabilities and user-friendly interface, the 900 Series is the perfect tool for any business looking to improve the performance of their products. Its powerful software allows for real-time analysis of gear and bearing materials, delivering instant feedback on their properties, which can drive informed decisions about how to improve their lifespan.

Whether you’re in the aerospace industry, automotive industry, or any other industry that relies on high-performance gearboxes and bearings, the 900 Series analyzer can help you improve and optimize their performance. Its cutting-edge analysis capabilities and proven performance make it the best choice for analyzing gear geometry and materials, ultimately improving product lifespan.

So why wait? Contact Data Physics today to learn how the 900 Series can help you improve the performance of your products and take your business to the next level.

Access SignalCalc Dynamic Signal Analyzers Literature

Download data sheets and brochures in pdf format.