The demand for very large force shaker systems is increasing. Typically this is met with large electrodynamic shakers (approximately 45klbf to 60klbf). However, larger shakers have limited frequency range. Shakers with 50,000 lbf shakers typically operate to about 2.5 kHz. Larger shakers can have maximum usable frequency ranges of less than 1.5 kHz. The reason for this reduction in performance is that high force requires larger armature resulting is a lower first resonance frequency thus reducing the useful bandwidth of the shaker.

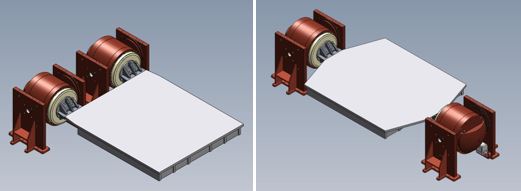

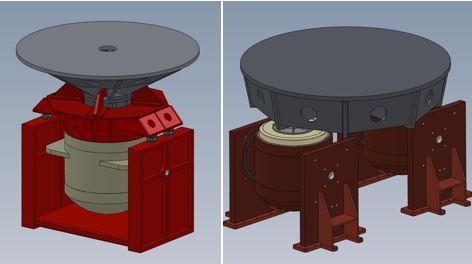

While a dual shaker configuration will require additional table and head expander complexity, the added mass of the head expander and overall size and complexity of the structure may not be that different from a single large shaker setup. In some cases, the overturning moments may require a guided head expander. If the head expander or slip table is not restrained in cross axis motion, spherical couplings may be required to deal with foreshortening.

Advancements in multi shaker control technology have made multi shaker single axis testing more practical. Older technology used a single shaker controller to drive two shakers, sometimes with a constant phase shift network. Due to dynamic response and unbalanced load, constant phase difference is not adequate. Due to dynamic response and unbalanced force between the two shakers, single drive magnitude is not adequate. A better solution is provided by a multi shaker controller that uses the 2X2 transfer function matrix to drive each shaker with an individual magnitude and phase signal across the frequency bandwidth.

Multi shaker control for dual shaker single axis testing is the same whether the configuration is driving a head expander for vertical testing or a slip table for horizontal testing. There is also no difference in control strategy when driving a slip table in either a push-push or push-pull configuration. The SignalStar Matrix multi shaker controller is capable of Random, Sine, Shock (including SRS), Time Replication and Mixed Mode (ROR, SOR) testing. It is also capable of acceleration or force limiting.

Larger test articles can also have large overturning moments caused by non-symmetrical loading or resonances in the fixture or test article. One of the benefits of dual shaker testing is that two shakers can act to restrain overturning moments. Another benefit to dual shaker testing is the ability to excite test articles whose dimensions are so large that they could not be tested on a single large shaker without extensive heavy fixturing (figure 3).

In summary, a dual shaker system can achieve equal or greater force and frequency range than a single large shaker while the cost is comparable with a single large shaker system. A dual shaker system has the additional benefit that the shakers may be separated and used as individual shaker systems for testing to higher frequency bandwidth, extending the usefulness of the large shaker system. If equipped with spherical couplings, then the system can also be used for some multi DOF testing.