Data Physics is in the process of completing multiple electrodynamic shaker systems to allow a prestigious test house and their automotive customers to test a complete range of batteries for electric vehicle development programs.

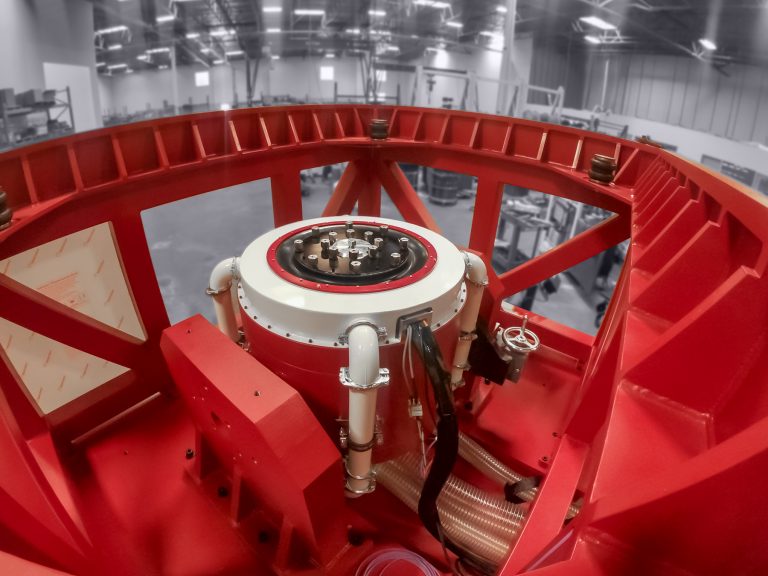

The Data Physics SignalForce™ electrodynamic shakers are capable of testing payloads of over 750 kg on the purpose-built head expander and slip table assemblies. To date, two shaker systems have completed final customer acceptance testing in our factory in Corona, California and are currently in transit to Europe for integration at the customer site.

Two matching, dedicated vertical systems feature Data Physics’ LE-1316-3 shakers, which generate up to 60 kN force (Sine and Random), were built with several modifications to accommodate the battery test environment.

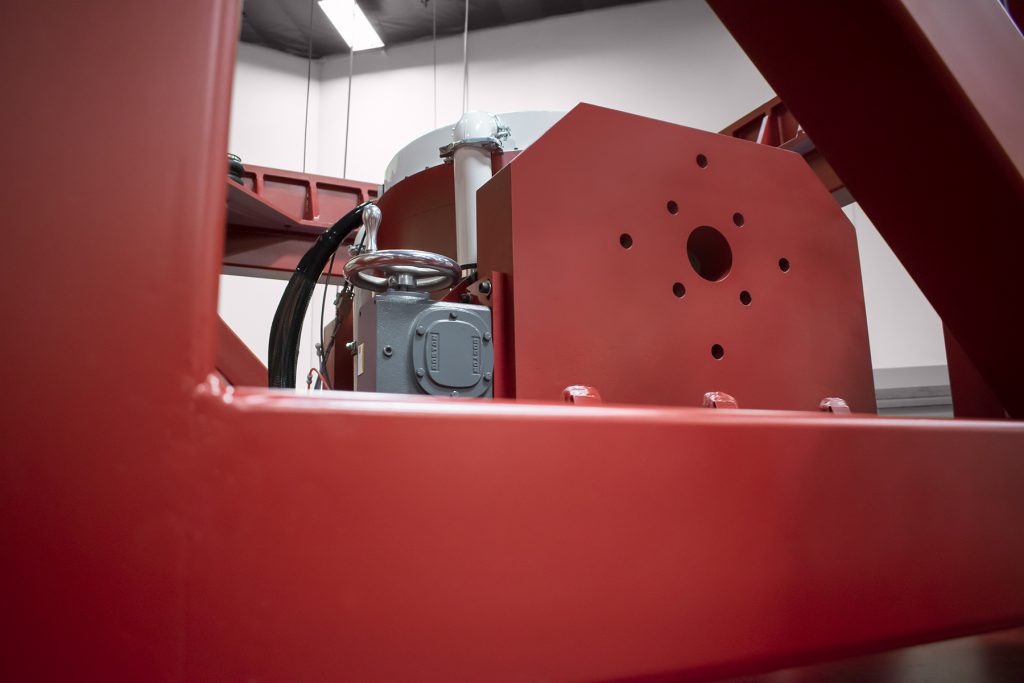

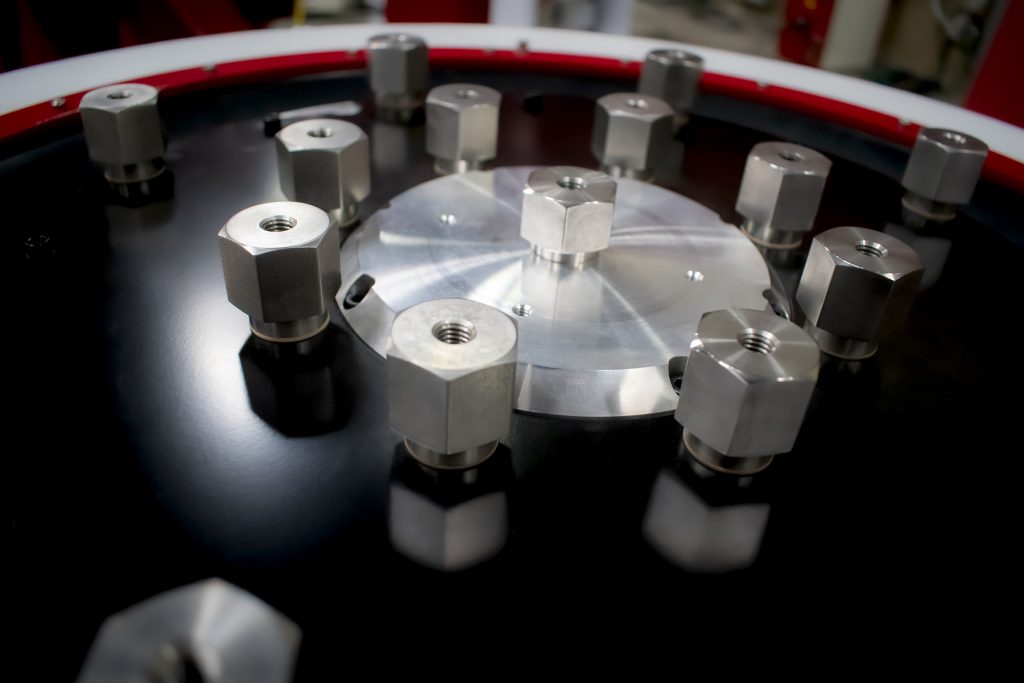

The guided vertical head expanders have a mounting area of 2.5 m x 1.5 m and were FEA modeled to accommodate testing to 2 kHz, when necessary. The specific size and shape allow for testing the latest EV batteries which typically reside in the floor of the electric vehicle. The head expander design features special external guidance and load support for the head expander, protecting the shaker armature and test article in case the battery under test creates offset loads. In the event a thermal runaway condition is sensed during testing, the system’s unique side panels and diaphragm act to protect the shaker from fire extinguishing agents, which are deployed to prevent a catastrophic fire.

Images show one of the battery testing systems before installation of the head expander.

A third system (not pictured) with the same customer features a Data Physics LE-5022-3 water-cooled electrodynamic shaker system. Situated in a sub floor-level chamber, the system’s 1.2 m x 1.2 m slip table and vertical head expander are integrated with a climatic chamber and sealed with a diaphragm.

In the event a thermal runaway condition is sensed during testing, the specially designed chamber is designed to flood the battery with up to 1,000 liters of water to extinguish any resulting fire. The purpose-built shaker system is designed to support the added mass of the water, in addition to having a sealing surface to accommodate the water immersion.

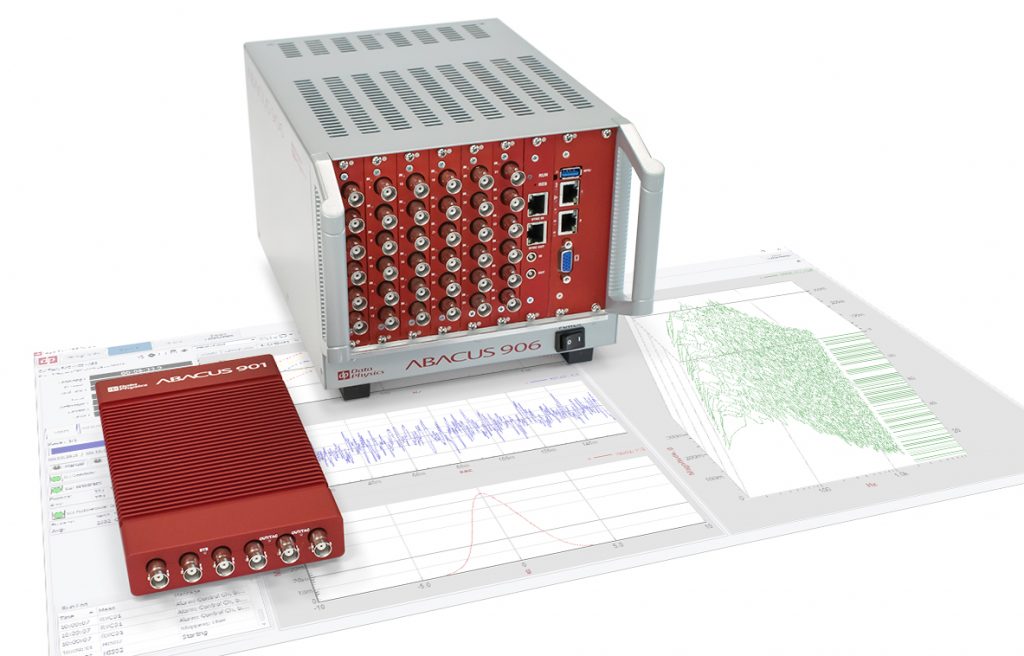

Each battery testing system will be controlled by Data Physics’ latest generation 900 Series vibration controller, incorporating distributed real-time digital signal processing and advanced control algorithms for accuracy and safety. The 900 Series controllers include software for random, sine, shock, and resonance dwell control.

Contact Data Physics to learn how can we help advance your automotive testing and development initiatives.