The question of “when do we have to choose the optional welded magnesium Drive Adapter” has come, so we wanted to take this opportunity to explain the typical rule of thumb for selecting a Drive Adapter versus just the standard in-line drive connection.

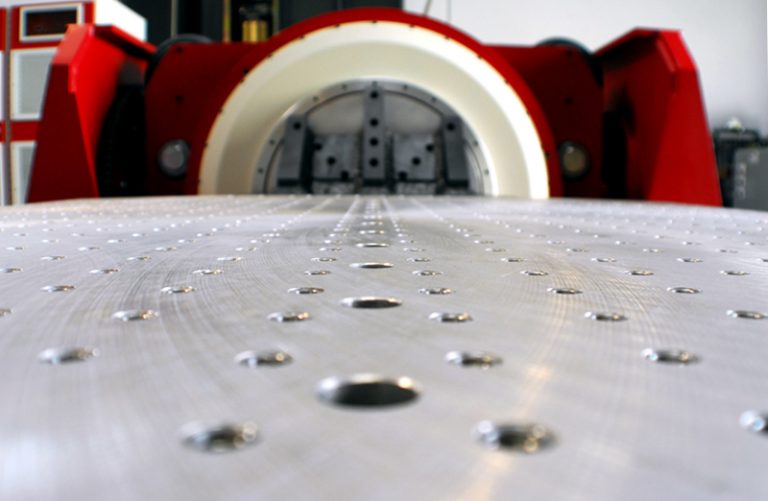

Typically, the SignalForce MST-XX Monobase systems include a simple in-line drive connection. This is usually a simple removable plate that connects the slip plate to the central horizontal row of inserts on the shaker armature. This connection is well suited for small lightweight packages – less than 100 lbs (45 kg), typically with oil film slip tables or even with low pressure guide bearings. However, if the customer is planning on testing larger payloads with high overturning moments, the welded magnesium Drive Adapter is recommended.

To go one step further, when the slip table system uses high pressure hydrostatic journal bearings or low pressure T-Film bearings, the welded magnesium Drive Adapters should always be used. The Drive Adapter is designed to allow maximum transmission of force into the slip plate, with minimal losses across the bolted joint. This design has proven to have the best dynamic characteristics of any drive configuration available and has been adopted across the entire shaker industry.